The Facts About Aluminum Castings Company Uncovered

Table of ContentsHow Aluminum Castings Company can Save You Time, Stress, and Money.A Biased View of Aluminum Castings CompanyAbout Aluminum Castings CompanyNot known Facts About Aluminum Castings CompanyMore About Aluminum Castings CompanyThe Greatest Guide To Aluminum Castings CompanyWhat Does Aluminum Castings Company Mean?

The enhancement of silicon can improve the fluidity of the alloy and minimize thermal shrinkage, making the casting simpler to load the mold and mildew and reducing the generation of pores. Mainly utilized in car engine parts, hydraulic parts, cylinder heads, and so on. Light weight aluminum copper alloy (Al-Cu) Includes light weight aluminum and copper, in some cases with percentages of nickel and manganese added.Blowing up aluminum components These optional finishes give flexibility and functionality, enabling makers to customize the look and performance of aluminum parts to specific requirements and applications. Naturally, the cast aluminum itself can also be done without surface treatment. You can review this post to read more regarding metal surface treatments: "15 Sorts Of Sheet Steel Parts Finishing Options." Tipping into everyday life, we frequently come throughout actors light weight aluminum parts.

The Of Aluminum Castings Company

Each example showcases the versatility and functionality of cast aluminum in day-to-day life. This post supplies info about actors aluminum, from the spreading procedure to comparisons with cast iron and functioned aluminum, its advantages, common basic materials, optional coatings, and numerous actors aluminum manufacturing products. Whether you are discovering prototyping solutions for a new item or want to place an existing item right into manufacturing, please contact us and we have expert designers to aid you.

An Unbiased View of Aluminum Castings Company

- Cast aluminum products might have inner flaws such as pores and inclusions, which influence their toughness and performance.

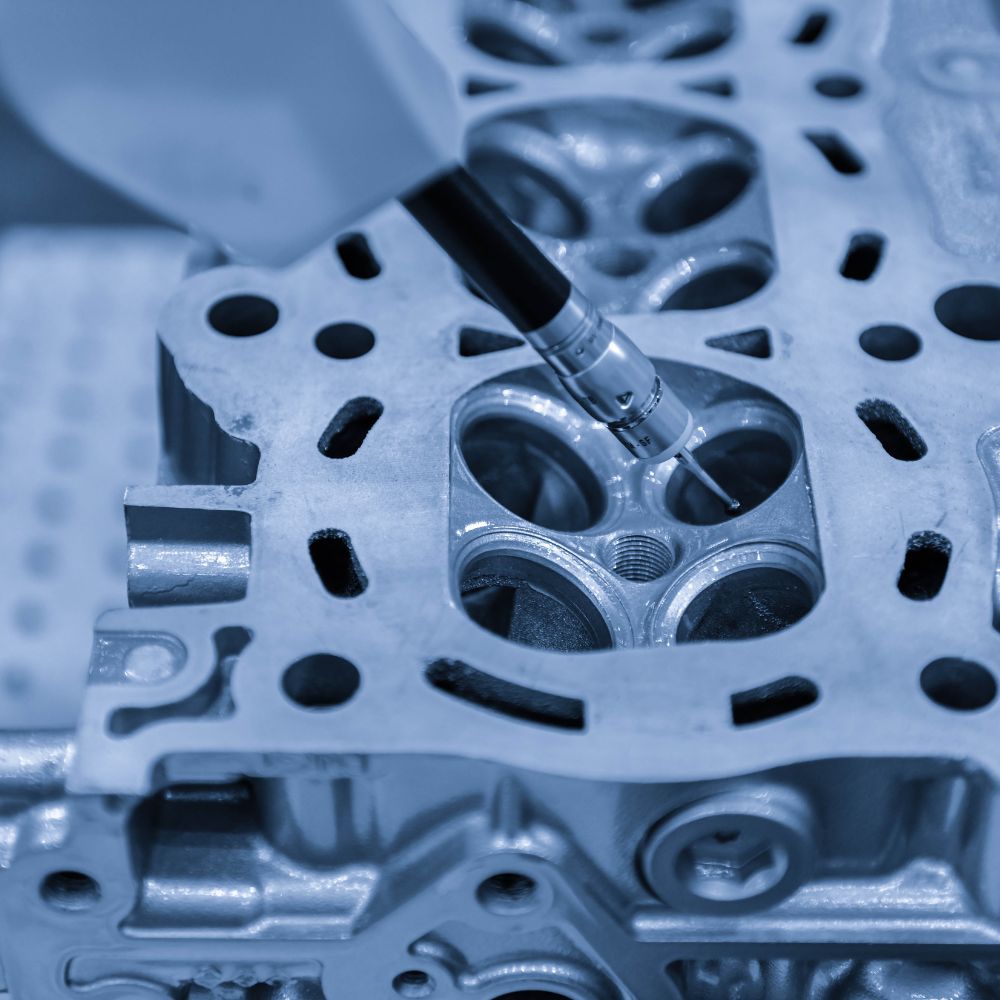

(Picture resource: Internet) Aluminum casting is an approach for generating high resistance and excellent quality components by putting molten light weight aluminum into a specifically designed and accuracy engineered die, mold and mildew, or form. It is an efficient procedure for the manufacturing of facility, elaborate, in-depth components that exactly match the requirements of the initial style.

Things about Aluminum Castings Company

This certain procedure is just one of several approaches made use of to generate light weight aluminum spreadings, each of which is used for the creation of specific kinds of components - Sand Molding. A variation in the spreading procedures is the kind of mold, which can be completely made from steel or briefly made from a non-metallic product

In order to talk about the light weight aluminum casting process, it is essential to take a look at each of the various distinct methods and exactly how they are used given that there isn't just one procedure. There are producers that specialize in one or a number of approaches, numerous producers use clients a selection as to which procedure they would certainly choose.

An Unbiased View of Aluminum Castings Company

From the smallest electrical component weighing much less than a gram to transmission coverings and clutch housings for cars, casting generates each component specifically to the requirements of the layout, faultlessly with little need for completing. The arrival of aluminum casting has actually supplied designers the opportunity to make any type of kind of arrangement with the assurance that the part will execute up to assumptions.

Computerization has actually enhanced the pressure to be with the ability of promptly deliveries to fulfill client needs (https://sandbox.zenodo.org/records/397992). As the need for boosted efficiency and efficiency grows, aluminum die casting has actually been even more than qualified of meeting and surpassing what has actually ended up being called for. Components, components, and workpieces are produced at a high rate of rate that is faster than any other sort of alloy

The Main Principles Of Aluminum Castings Company

(Picture source: Internet) Though aluminum spreadings are remarkably solid and lightweight, they have a really positive look and visual value. There are several uses for light weight aluminum casting that do not need them to be seen or have an enjoyable appearance.

Every sector is looking for means and approaches to reduce expenses yet create premium quality items. The reduced expense of the light weight aluminum spreading process is a significant element in why firms are picking it for product growth. Much of the expense savings is due to the rate of manufacturing and the removal of the demand to finish completed products.

When light weight aluminum castings are revealed to the air, their surface ends up being oxidized, which is a characteristic of the metal. This one aspect is the factor that light weight aluminum spreadings have longevity and integrity. This boosted life time offers customers with higher worth (https://www.startus.cc/company/aluminum-castings-company). * Resource:.

The 10-Minute Rule for Aluminum Castings Company

This article has all the info you require to know regarding light weight aluminum casting (Sand Molding). You will find out concerning subjects such as: What is light weight aluminum casting? Aluminum casting processes Aluminum alloys Benefits of aluminum spreading And a lot more Aluminum spreading is the procedure of putting liquified aluminum right into specially crafted dies, molds, or go to my site forms to make get rid of high precision and remarkable high quality

It is worth keeping in mind that the preliminary creation, CNC machining, and tooling of these durable mold and mildews is labor-intensive and needs upfront financial investment, which need to be taken into consideration when reviewing total production prices versus various other casting approaches such as sand casting or low-pressure spreading. In spite of this, the long-term benefitssuch as minimized per-unit cost, extraordinary part uniformity, and much shorter lead timesoften outweigh the initial configuration expenditures for mid- to large light weight aluminum casting tasks.

The mold is diligently engineered to match the specific geometric shape and casting resistance required for the partoften split right into two or more fifty percents (often called die halves). During steel casting, these fifty percents are secured firmly with each other to avoid the intro of air, pollutants, or additions, making certain a dense and defect-free structure.